CNC Breakout Board vs. CNC Controller: Key Differences Explained

CNC Breakout Board vs. CNC Controller: Key Differences Explained

Understanding the distinction between a breakout board and a CNC controller in automation systems.

In the world of computer numerical control (CNC) machining, understanding the relationship between the breakout board and the CNC controller is crucial. These two components often work together, yet they serve very different purposes within the automation system. Confusing one for the other can lead to compatibility issues, signal errors, or inefficient performance. This article explores the core differences between CNC breakout boards and controllers, explaining how they interact and why both are essential for precise machine operation.

1. The Role of the CNC Breakout Board

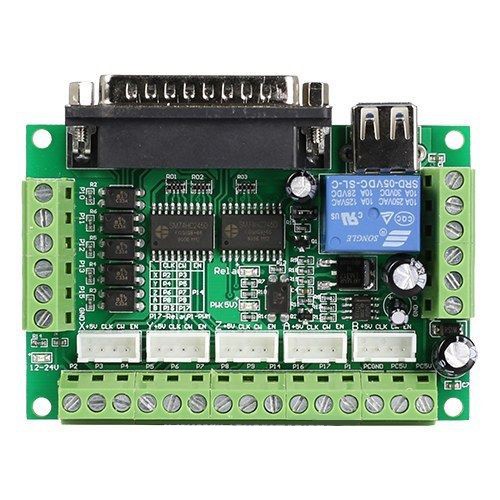

A CNC breakout board (BOB) acts as the interface between the computer’s control signals and the CNC machine’s hardware. It distributes, isolates, and conditions electrical signals that travel between the motion controller and the machine’s stepper or servo drivers.

In simple terms, the breakout board “breaks out” the complex wiring connections from the controller into manageable terminals. This makes it easier to connect inputs (like limit switches, emergency stops, and sensors) and outputs (such as spindle controls or coolant pumps).

A high-quality breakout board also offers electrical isolation through optocouplers, protecting sensitive components from voltage spikes or noise interference. Without this intermediary layer, the communication between the control computer and the machine hardware would be unstable and prone to electrical faults.

Picture from: ST-V2

2. The Function of the CNC Controller

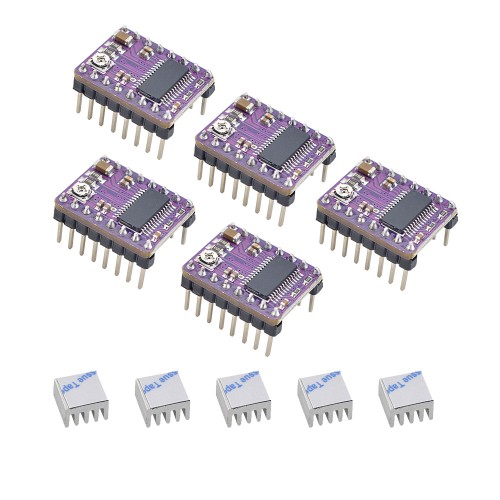

The CNC controller is the brain of the CNC system. It interprets G-code commands—the digital instructions that define the toolpath—and converts them into motion control signals. These signals determine how each axis moves, at what speed, and in what sequence.

There are two main types of CNC controllers:

PC-based controllers, which use software such as Mach3, Mach4, or LinuxCNC running on a computer.

Standalone hardware controllers, which operate independently with dedicated firmware and real-time processing capabilities.

Unlike a breakout board, the controller makes logical decisions, processes motion algorithms, and handles synchronization between machine axes. Essentially, the controller provides the intelligence, while the breakout board provides the connectivity.

Picture from: 5-DRV8825

3. Key Differences Between the Two

The distinction between a CNC breakout board and a controller lies in their functionality, complexity, and processing role.

Purpose: The breakout board handles signal routing and protection, whereas the controller handles motion control and logic processing.

Processing Power: The breakout board contains no computational logic—it simply passes and isolates signals. The controller, on the other hand, performs mathematical computations and executes G-code instructions.

Software Dependence: A breakout board cannot run CNC programs by itself. It requires a controller or PC-based software to generate motion signals.

Design and Cost: Breakout boards are typically simple and inexpensive, while controllers are more advanced and costlier due to their processing components.

In short, a breakout board is like a translator that helps the controller “speak” safely to the hardware components.

4. How They Work Together

For a CNC system to function effectively, both the controller and breakout board must operate in harmony. The typical signal flow looks like this:

CNC software or controller processes the G-code.

The controller sends step and direction signals to the breakout board.

The breakout board routes these signals to the stepper or servo drivers, while managing additional input/output tasks.

The drivers then move the motors based on those signals, completing the motion loop.

This layered design ensures flexibility, safety, and easier troubleshooting. If something fails, the user can often replace or upgrade one component—controller or breakout board—without rebuilding the entire system.

5. Choosing the Right Combination

Selecting the right breakout board and controller pair depends on your CNC machine’s size, complexity, and performance requirements. For hobbyists or smaller systems, a USB or Ethernet breakout board paired with a PC-based controller like Mach4 offers an affordable and flexible setup. For industrial-grade machines, a standalone motion controller with a high-end breakout board ensures better reliability and real-time precision.

When choosing, always verify compatibility in terms of voltage levels, signal types, and interface protocols. Using mismatched components can cause erratic motor behavior or communication loss.